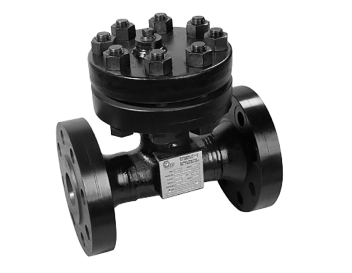

Fabricated Tee Strainers

Companies in several industrial sectors need a cost-effective mechanism for removing heavy solids while maintaining high flow rates. Hellan Fluid Systems, a leading manufacturer of fabricated T-strainers and other filtering and straining solutions, is the source for fabricated tee strainers, a popular choice for numerous industries.

T-Type Strainer Industries

Many industries moving liquids must mechanically remove particulates from their lines to prevent clogging or contamination in sensitive processing equipment such as pumps, meters, control valves, and regulators.

T-strainers have become proven, cost-effective solutions to remove unwanted material from product flows. The devices are especially useful in space-constrained environments where maintaining high flow rates is imperative, larger pipelines, and applications requiring special features. They’re also a valuable choice for situations where blowdown ports aren’t an option, such as removing the filter basket without draining the fluid.

Hellan Fluid Systems, a leader in fluid filtration technologies, manufactures a complete range of T-type strainers and SSI T strainers for a range of industries, including:

- Process equipment

- Power generation

- Steam, liquid, gas, and oil service

- Pulp and paper

- Chemical

- Water & waste

- Metal & mining

What Does Fabrication Provide?

T-type strainers can be furnished with single or double-wedge basket designs to meet open-area requirements. Numerous types of cover options. From bolted, slip-hinged, knob, swing-away, quick opening, or davit swing arm assembly allowing for ease in maintenance.

Quick opening and davit swing arm assembly covers allow for a single maintenance engineer to manage the cleaning of the unit reducing maintenance costs and downtime.

Custom Fabricated Tee Strainers

We can manufacture custom-fabricated T-strainers to fit any combination of unique requirements:

- Capable of pressures up to 3705 PSIG and temperatures up to 800°F

- Numerous materials:

- Carbon steel

- Stainless steel

- Other materials on request

- Buttweld ends and RTJ or RF flanges are available as end connections under ASME 16.34 and 16.5

- Numerous options, including:

- Three flow configurations are available

- Horizontal or vertical installations

- Stainless steel perforated screens and thru-bolt covers are standard

- Cover lifting lug standard on sizes 10” and larger

- Oxygen cleaning

- Internal/external coatings

- NACE MRO10-75

- Vent, drain, and differential pressure connections

Contact us today to learn more about our fabricated tee strainers or our other types of strainers, including Y-Type Strainer.

Industries

Hellan Strainers are used in all industries that require the collection and removal of particulate from fluid systems. Listed below, are just a few of the ways Hellan provides industrial solutions to the global market.

Our Quality

Hellan Fluid Systems' self-cleaning fluid strainers are ISO9001 certified, meet all Navy Mil-Spec requirements, are approved by the American Bureau of Shipping and Lloyd’s Register, are listed by Underwriters Laboratories and designed in accordance with API, ASME, and PED.