Staples & Pfeiffer

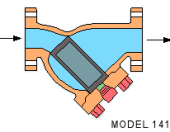

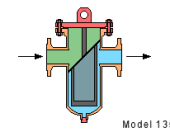

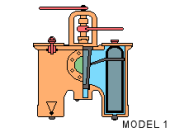

The Staples & Pfeiffer strainers line has a proven track record in quality and reliability since the early 1900’s. Staples & Pfeiffer products are used in both military and commercial applications and can be categorized by one of the following three styles: Y-type, Simplex, or Duplex. Their primary function is to strain impurities from water, steam, oils, and chemicals. They are capable of serving many industries but are most commonly utilized in Navy ships, Coast Guard ships, oil refineries, and power plants.

Please contact us by calling (888) 443-5526 or emailing us at hellansales@hellanstrainer.com for more information about Staples & Pfeiffer strainers.

Hellan Strainers Materials

Our Staples & Pfeiffer Y, Simplex, and Duplex Materials are available in Bronze, Steel and Stainless Steel.

Industries

Hellan Strainers are used in all industries that require the collection and removal of particulate from fluid systems. Listed below, are just a few of the ways Hellan provides industrial solutions to the global market.